Friday, November 8, 2013

Post 10. Final evaluation

Thursday, November 7, 2013

Post 9

Post 8

Tuesday, November 5, 2013

post 7

Thursday, October 24, 2013

Post 6

Tuesday, October 22, 2013

Post 5

Friday, October 18, 2013

post 4

I've also done the small circle for another side of the stick, but I still need to make a hole of a right size. So next lesson I will finish doing that, and then I'll start making the cams, I will need two offset cams for the ships and three for the waves. That's my plan for the next lesson. But if I'll finish doing that, which is unlikely to happen, but if I do, I will start cutting the design of my top part of the toy.

That's my box and the small circle that I am going to finish next lesson.

Wednesday, October 16, 2013

post 3

Friday, October 11, 2013

Post 2

Wednesday, October 9, 2013

Term 4, post 1

Wednesday, September 4, 2013

post 13

Evaluation of your design in terms of aesthetics, function, ergonomics and economics.

Aesthetics.

Well, my design looks alright. However, my first design was quite different but during the process, i realized that it wouldn't work and had to change it. The new design looks pretty good and modern, but when I was gluing the part together, the boxes moved and they are not perfect rectangles, but fortunately it cant we seen, if you don't know about it.

function

My desk tidy is still i the workshop and haven't check it. But I recon its function is going to be good. As I'm going to give it to my mom and she has a lot of jewellery, my present will be really suitable. The desk tidy is green, which is her favourite colour, so it is another positive aspect of this project. It doesn't take much space which is good, because it has to contain a lot of things but occupyeconomics

Tuesday, August 27, 2013

Post 12, question 4

Thursday, August 22, 2013

Post 11. Desk tidy is completed and ready to be used! :)

Tuesday, August 20, 2013

Post 10

When I' ll finish all of the things that I want to and when I' ll fix all the problems that I have, my desk tidy will look good and will help me to organize things on my desk:)

That's what I have so far:

Monday, August 19, 2013

Post 9, research question n. 3

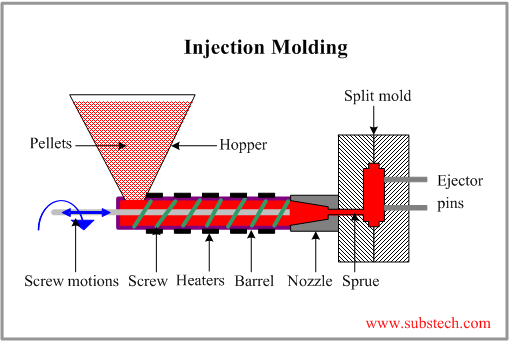

Polymer material in form of pellets is fed into an Injection Molding machine through a hopper. The material is then conveyed forward by a feeding screw and forced into a split mold, filling its cavity through a feeding system with sprue gate and runners.

Injection Molding machine is similar to Extruder. The main difference between the two machines is in screw operation. In extruder screw rotates continuously providing output of continuous long product (pipe, rod, sheet). Screw of injection molding machine is called reciprocating screw since it not only rotates but also moves forward and backward according to the steps of the molding cycle.

It acts as a ram in the filling step when the molten polymer is injected into the mold and then it retracts backward in the molding step.

Heating elements, placed over the barrel, soften and melt the polymer.

The mold is equipped with a cooling system providing controlled cooling and solidification of the material.

The polymer is held in the mold until solidification and then the mold opens and the part is removed from the mold by ejector pins.

Injection Molding is used mainly for Thermoplastics, but Elastomers and Thermosets are also may be extruded. In this case cross-linking occurs during heating and melting of the material in the heated barrel.

A principal scheme of an Injection Molding Machine is shown in the picture.

Injection Molding is highly productive method providing high accuracy and control of shape of the manufactured parts. The method is profitable in mass production of large number of identical parts.

Thermoplastics commonly used in Injection Molding are as follows:

Injection Molding is used for manufacturing DVDs, pipe fittings, battery casings, toothbrush bases, bottle lids, disposable razors, automobile bumpers and dash boards, power-tool housing, television cabinets, electrical switches, telephone handsets, automotive power brake, automotive fascias, transmission, and electrical parts, mirror housings, steam irons, washer pumps, spoilers, butter tubs, moisture vaporizers, yogurt containers, toilet seats, cell-phone housings, cradles or bases for personal digital assistants, case of a notebook-computer, computer mouse, electrical connector housings, lawn chairs, automotive ashtrays, and cookware appliance handles and knobs, aerosol caps, household items, bottle caps, toys.

Post 8, research question 2

Thursday, August 15, 2013

Post 7

Tuesday, August 13, 2013

post 6, question 1

- Only one person using the machine at one time

- Any hair should be tied back or in a hair cap

- when cutting the pieces, if one of the pieces should be moved, don't move it with your hands, sue something else to move it and then pick it up

- if dropped something, don't go down with your head close to the machine, move it with your foot and then pick it up

- Safety glasses must be worn

2) SANDER:

Considerations that should take place:

- Safety glasses must be worn

- Make sure sanding disc and belt is in good condition

- Make sure you know what direction the belt and disc in going

- don't put hands too close to sander

- hair should be always tied at the back

- just one person in each work area

Thursday, August 8, 2013

5 post

On last lesson I've done just 2 boxes, so next lesson I have to do so much work to do, as our project has to be finished at the end of week 5 or on the first lesson of week 6. Because we have to start doing our theory research questions.

Here is plan for me to complete on the next lesson:

1) Glue two boxes

2) Band 2 other pieces and make 2 more boxes

3) And finally glue everything together.

Tuesday, August 6, 2013

4 post

Monday, July 29, 2013

3 post

Thursday, July 25, 2013

2nd post

Tuesday, July 16, 2013

term 3, post 1

-I really like this desk tidy because there is a space for the phone, some paper, pens, pencils and small things.

-I really like this desk tidy because there is a space for the phone, some paper, pens, pencils and small things. -this one looks modern, interesting, good for teenager, but there is no place for my phone and a cup, so I don't think this design will be the best for me.

-this one looks modern, interesting, good for teenager, but there is no place for my phone and a cup, so I don't think this design will be the best for me. -This desk tidy includes a lot of different trays for paper, small things,etc. But I don't really like the way it's done and I think that this desk tidy will take a lot of space on my table.

-This desk tidy includes a lot of different trays for paper, small things,etc. But I don't really like the way it's done and I think that this desk tidy will take a lot of space on my table.Wednesday, June 5, 2013

5th post

I've done my base, aluminium piece and the LED bulbs and put al the parts together. I had some trouble with turning the pieces and putting them under one angle. But yesterday Mr Andrews showed us how to do it. It was still confusing but I tried couple of times and then I finally got the right angle I wanted and put all the pieces togeter.

this is the picture of my finished lamp

Thursday, May 30, 2013

4th post

I've finished my aluminum piece and timber piece, I needed just to put these two together so that they are connected. But the problem was that they were on different angle and I don't know how to make them be on the same angle. So, on the next class I will have to borrow a book and look it up.

Term 2 questions.

CAD stands fro Computer-Aided Design

A prototype is an early sample or model built to test a concept or process or to act as a thing to be replicated or learned from. It's important because that us how you can check whether your project is going to work or not. If not, how can you fix it and make it better.

Rapid Prototyping (RP) enables the quick fabrication of physical models using three-dimensional computer aided design (CAD) data. Used in a wide range of industries, Rapid prototyping allows companies to turn innovative ideas into successful end products rapidly and efficiently.

before rapid-prototyping, prototype should be sketched. To see the elementary design of all the details of the machine(project)

Additive manufacturing or 3D printing[1] is a process of making a three-dimensional solid object of virtually any shape from a digital model.

CNC means Computer Numerical Control. This means a computer converts the design produced by Computer Aided Design software (CAD), into numbers. The numbers can be considered to be the coordinates of a graph and they control the movement of the cutter. In this way the computer controls the cutting and shaping of the material.

A STL file is a format used by Stereolithography software to generate information needed to produce 3D models on Stereolithography machines.In fact, the extension "stl" is said to be derived from the word "Stereolithography." The surface of an object is broken into a logical series of triangles. Each triangle is uniquely defined by its normal and three points representing its vertices.

3rd post

But when I saw it and deleted it, everything was good.

That what I got at the end of the lesson.

On today's lesson, I'll probably start doing my timber piece which is a base of my lamp.

Thursday, May 23, 2013

2nd post

I finished doing my IPhone and started working on the design of my lamp. But unfortunately I had just time to make a shape of my lamp.

Next lesson I will work on the shape of my lamp and the actual lamp.

Wednesday, May 22, 2013

Term 2. 1st post

I was so confused with making design of my IPhone, but I think it's all good now.

We also have questions that we have to answer, which then will help us to write a 500-words paragraph about design technology and the ProDesktop.

I nearly finished my iPhone, I think I'll need 10 minutes on the next lesson to finish it and them I'll start working on my lamp.

I'm also half trough the questions.

Thursday, March 21, 2013

Questions

What is the actual difference between light of different colours?

The frequency of the EM wave determines the amount of amount energy it contains. Therefore, different colors of light have different frequencies and amount of energy.

How slow can we make light go?

When light passes through different media its speed slows. The slowest speed recorded is through sodium at -272 C during which the speed of light fell to 60kph – about the speed of a bicycle.

3. What does light symbolise in the following painting of the Greek god Prometheus wielding the flame of a torch?

It symbolizes the fact that The Prometheus came to people to give people light. Another reason is probably that he came to help people and here the light could be defined as help.

4. Fill in definitions for the following lighting concepts:

Ambient light

The soft indirect light that fills the volume of a room with illumination.

Direct light

Illumination on a subject or area that goes directly from the front of the luminaire in a straight line to the subject

Warm white

“Warm white” is the same colour temperature as the standard inefficient incandescent, imparts a more orange/red light on objects, is normally associated with red or orange objects.

Diffuser

A light fixture, such as a frosted globe, that spreads light evenly.

Watts

An International System unit of power equal to one joule per second.

Luminosity

the quality of being luminous; emitting or reflecting light; "its luminosity is measured relative to that of our sun"

Efficiency

The ratio of the energy delivered (or work done) by a machine to the energy needed (or work required) in operating the machine.

5. Fill in the table below describing the different kinds of lighting available:

Picture Name Feature Use

Ambient light Light source is covered by diffuser This type of light source is mainly used to provide the scene with a basic view of the different objects in it. Eg. Desk lamp

Spot light Bright, direct light, narrow beam, no diffusion. searchlights or spotlights are used in advertising, fairs, festivals and other public events. Eg. Lights in the art center

Pendant light Light can be diffused or directed down; hangs from ceiling; usually a design feature. Pendant lights are often used in multiples, hung in a straight line over kitchen countertops and dinette sets or sometimes in bathrooms. Eg. Lights in the bathroom

Task light Light points downward; often articulated; no direct light to eyes. Often task lighting refers to office lighting, where the task light is used to increase illuminance on the reading area. Eg. Desk light

LEDs come in several shapes. List three kinds of lighting they can replace.

a. Standard

b. Globe

c. Candle

Evaluation

Comment of the following Design Aspects of your ecolamp:

Ergonomic

Aesthetics

Function

Economics

The lamp that I did looks good. The design looks interesting and it could be put in any room with any design style because it's base which is made of timber and it's wooden colour and the aluminium piece will also look good with everything really. And because the lamp is going to be a present for my mother and we'll probably put it in her office. All the furniture that is there, is wooden so the lamp is going to be in perfect balance with the style of her office. The shape of my lamp is also fashionable, doesn't take a lot of space, what is really good for the offices because there is always not enough space.

The lamp is bright and it lights up quite a big space. What is also good because sometimes my mother stays at work late and therefore she needs a lot of light. The LEDs are putted just at the end of aluminium piece so that the light coming from it wouldn't be too bright or too dim. Because on the lamp is LED light, it saves quite a big amount of energy and therefore it saves that extra amount of money that my mother payed for the light from normal light bulbs.

Insert a colour photograph of your finished LED lamp.