Tuesday, August 27, 2013

Post 12, question 4

Thursday, August 22, 2013

Post 11. Desk tidy is completed and ready to be used! :)

Tuesday, August 20, 2013

Post 10

When I' ll finish all of the things that I want to and when I' ll fix all the problems that I have, my desk tidy will look good and will help me to organize things on my desk:)

That's what I have so far:

Monday, August 19, 2013

Post 9, research question n. 3

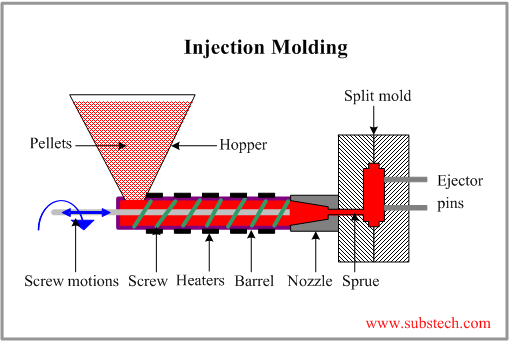

Polymer material in form of pellets is fed into an Injection Molding machine through a hopper. The material is then conveyed forward by a feeding screw and forced into a split mold, filling its cavity through a feeding system with sprue gate and runners.

Injection Molding machine is similar to Extruder. The main difference between the two machines is in screw operation. In extruder screw rotates continuously providing output of continuous long product (pipe, rod, sheet). Screw of injection molding machine is called reciprocating screw since it not only rotates but also moves forward and backward according to the steps of the molding cycle.

It acts as a ram in the filling step when the molten polymer is injected into the mold and then it retracts backward in the molding step.

Heating elements, placed over the barrel, soften and melt the polymer.

The mold is equipped with a cooling system providing controlled cooling and solidification of the material.

The polymer is held in the mold until solidification and then the mold opens and the part is removed from the mold by ejector pins.

Injection Molding is used mainly for Thermoplastics, but Elastomers and Thermosets are also may be extruded. In this case cross-linking occurs during heating and melting of the material in the heated barrel.

A principal scheme of an Injection Molding Machine is shown in the picture.

Injection Molding is highly productive method providing high accuracy and control of shape of the manufactured parts. The method is profitable in mass production of large number of identical parts.

Thermoplastics commonly used in Injection Molding are as follows:

Injection Molding is used for manufacturing DVDs, pipe fittings, battery casings, toothbrush bases, bottle lids, disposable razors, automobile bumpers and dash boards, power-tool housing, television cabinets, electrical switches, telephone handsets, automotive power brake, automotive fascias, transmission, and electrical parts, mirror housings, steam irons, washer pumps, spoilers, butter tubs, moisture vaporizers, yogurt containers, toilet seats, cell-phone housings, cradles or bases for personal digital assistants, case of a notebook-computer, computer mouse, electrical connector housings, lawn chairs, automotive ashtrays, and cookware appliance handles and knobs, aerosol caps, household items, bottle caps, toys.

Post 8, research question 2

Thursday, August 15, 2013

Post 7

Tuesday, August 13, 2013

post 6, question 1

- Only one person using the machine at one time

- Any hair should be tied back or in a hair cap

- when cutting the pieces, if one of the pieces should be moved, don't move it with your hands, sue something else to move it and then pick it up

- if dropped something, don't go down with your head close to the machine, move it with your foot and then pick it up

- Safety glasses must be worn

2) SANDER:

Considerations that should take place:

- Safety glasses must be worn

- Make sure sanding disc and belt is in good condition

- Make sure you know what direction the belt and disc in going

- don't put hands too close to sander

- hair should be always tied at the back

- just one person in each work area

Thursday, August 8, 2013

5 post

On last lesson I've done just 2 boxes, so next lesson I have to do so much work to do, as our project has to be finished at the end of week 5 or on the first lesson of week 6. Because we have to start doing our theory research questions.

Here is plan for me to complete on the next lesson:

1) Glue two boxes

2) Band 2 other pieces and make 2 more boxes

3) And finally glue everything together.